PRODUCT

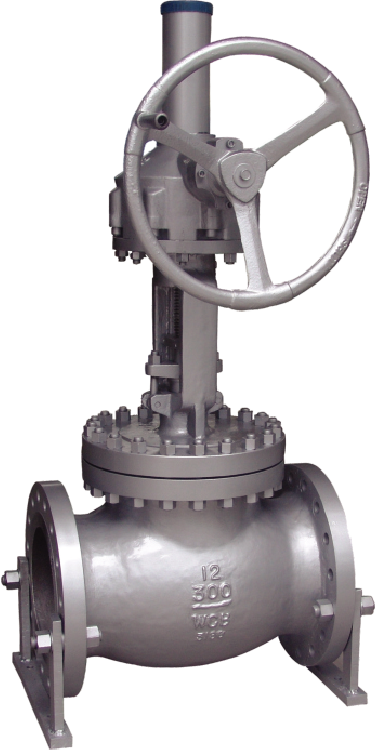

Globe valve

· Design

Cast steel globe valves are designed and manufactured to provide maximum service life and dependability.

All globe valve are full ported and meet the design requirements of American Petroleum Institute standard APl600 & 6D.BS EN 13709 and generally conform to American Society of Mechanical Engineers standard ASME B16.34.

Valves are available in a complete range of body/bonnet materials and trims.

· Ranges of materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of alloy and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Available Modifications

Trim changes

End Connection Modifications

Packing and Gasket Change

Operator Mounting

Handwheel Extensions

Pressures Equalizing

By-Pass

Customer Specified Coatings

Weld End Bore Changes

Oxygen & Chlorine Clearing & Packaging

Applicable standards

STEEL GLOBE VALVES BS 1873

STEEL VALVES, ASME B16.34

FACE TO FACE, ASME B16.10

END FLANGES, ASME B16.5

BUTTWELDING ENDS, ASME B16.25

INSPECTION AND TEST, API 598

Design descriptions

STRAIGHT PATTERN BODY DESIGN

OS&Y, OUTSIDE SCREW AND YOKE

BB, BOLTED BONNET

YOKE INTEGRAL WITH BONNET

RISING STEM AND HANDWHEEL

AVAILABLE WITH BG OPERATOR

LOOSE DISC, CHOICE OF PLUG OR BALL

RENEWABLE SEAT RING

IMPACT HANDWHEEL FOR 10″&ABOVE

HORIZONTAL SERVICE

FLANGED OR BUTTWELDING ENDS

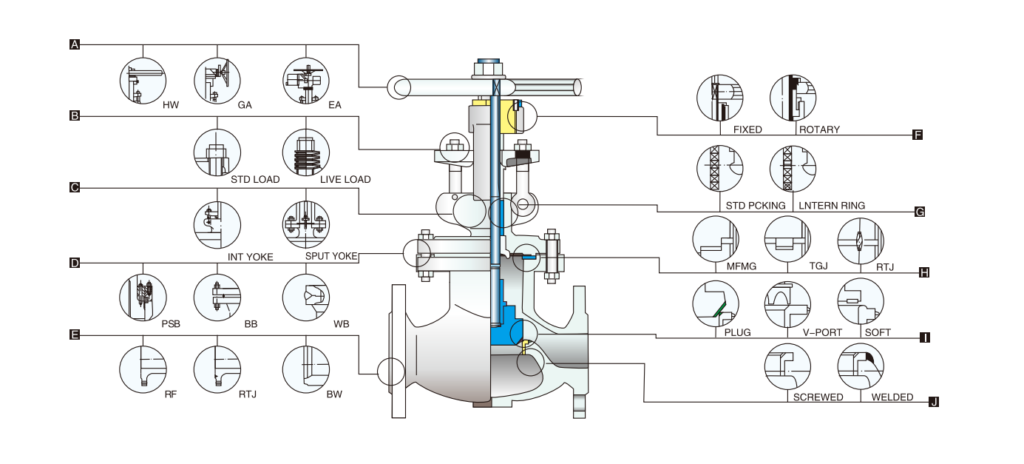

| Operation | Live Load Packing | OS&Y | BB | End Connections | |||||

|---|---|---|---|---|---|---|---|---|---|

| Large handwheels for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services. | In services requiring frequent cycling or with high pressure/temperature variations,live loading extends the service life between maintenance periods packing gland adjustments.Belleville spring are employed to provide constant packing gland stress. |

Outside screw and yoke. Cast steel globe valve yoke integral with bonnet for 10 & and smaller. | Bolted bonnet welding bonnet and pressure seal bonnet in services requiring frequent cycling or with high pressure/temperature variations. | A choice of flanged, RTJ flanged or buttwelding end for piping flexibility. | |||||

| Yoke sleeve | Lantern Ring And Double Packing Set | Body-to-Bonnet Joint | Disc | Seat Rings | |||||

| Furnished in aluminum bronze to reduce operating torque. Most size furnished with ball bearing yoke sleeves. |

lantern ring with leak-off fitting connection and double packing stack is optionally avaliable for critical services. | A male and female joint or tongue and groove joint is used 150Lb to 600Lb valves, ring joint is used in the body to bonnet connection in 900Lb & higher rated valves. | Plug disc is stem guided on all size. Disc has a differential angle front the seat to provide a line contact for maximum sealing. The bottom of v-port disc is fuided by the body seat ring for maximum disc stability in throttling applications, the soft teflon ring is excellent for lower temperature service where tight shut off required. |

Separate heavy duty, full ported rings for easy maintenance. Screwed or welded connection into body. |

|||||

| Gear box configuration | ||

|---|---|---|

| Class | Optional | Standard |

| 150Lb | 8"-12" | 14" Above grade |

| 300Lb | 8"-12" | 14" Above grade |

| 600Lb | 6"-10" | 12" Above grade |

| 900Lb | 4"-6" | 8" Above grade |

| 1500Lb | 2"-3" | 3" Above grade |

| 2500Lb | 2" | 3" Above grade |

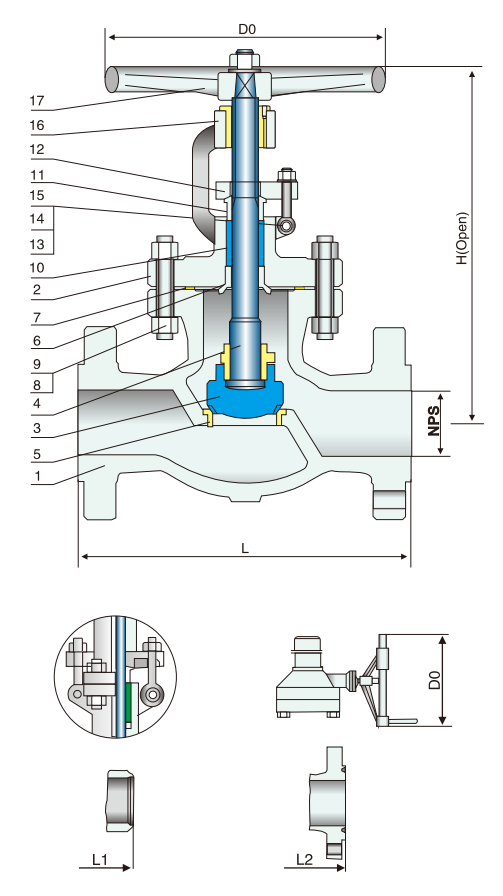

| Materials of parts | ||||

|---|---|---|---|---|

| No | Part Name | ASTM Material | ||

| Carbon steel | 1¼Cr-½Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A217-WC6 | A352-LCB |

| 2 | Bonnet | A216-WCB | A217-WC6 | A352-LCB |

| 3 | Disc | A105+CR13 | A182-F11+HF | A350-LF2+CR13 |

| 4 | Stem | A182-F6a | CR-MO-V | A182-F6a |

| 5 | Seat ring | A105+HF | A182-F11+HF | A350-LF2+HF |

| 6 | Stem Backseat | A276-420 | A276-304 | A276-420 |

| 7 | Bonnet Gasket | Steel Ring | 304SS Ring | Steel Ring |

| 8 | Bonnet Stud | A193-B7 | A193-B16 | A320-L7 |

| 9 | Bonnet Stud Nut | A194-2H | A194-7 | A194-4 |

| 10 | Packing | Graphite | ||

| 11 | Gland | A276-420 | A276-304 | A276-420 |

| 12 | Gland Flange | A216-WCB | A217-WC6 | A352-LCB |

| 13 | EyeBolt Pin | Carbon steel | A276-420 | Carbon Steel |

| 14 | Eyebolt | Carbon steel | A193-B7 | Carbon Steel |

| 15 | Eyebolt Nut | Carbon steel | A194-2H | Carbon Steel |

| 16 | Yokesleeve | Aluminum-Bronze | ||

| 17 | Handwheel | Malleable Iron | ||

| Note: 1) Ductile Ni-resist optional 2) Disc and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with facing as shown. |

||||

| Dimensional datas | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | DN | L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

||||||||||

| ANSI Class 150# | ANSI Class 300# | ||||||||||||||||||||

| 2 | 50 | 8.00 | 203 | 8.00 | 203 | 15.00 | 380 | 7 | 200 | 18 | 14 | 10.50 | 267 | 11.12 | 282 | 16.75 | 425 | 8 | 200 | 25 | 20 |

| 2½ | 65 | 8.50 | 216 | 8.50 | 216 | 21.00 | 535 | 10 | 250 | 30 | 22 | 11.50 | 292 | 12.12 | 308 | 19.00 | 485 | 10 | 240 | 32 | 22 |

| 3 | 80 | 9.50 | 241 | 9.50 | 241 | 17.50 | 445 | 11 | 280 | 41 | 33 | 12.50 | 318 | 13.12 | 333 | 19.88 | 505 | 11 | 280 | 38 | 27 |

| 4 | 100 | 11.50 | 292 | 11.50 | 292 | 20.25 | 515 | 11 | 280 | 64 | 43 | 14.00 | 356 | 14.62 | 371 | 22.50 | 570 | 13 | 320 | 56 | 41 |

| 6 | 150 | 16.00 | 406 | 16.00 | 406 | 22.00 | 560 | 13 | 320 | 86 | 72 | 17.50 | 444 | 18.12 | 460 | 25.25 | 640 | 16 | 400 | 96 | 75 |

| 8 | 200 | 19.50 | 495 | 19.50 | 495 | 24.25 | 615 | 13 | 320 | 110 | 88 | 22.00 | 559 | 22.62 | 575 | 33.25 | 845 | 18 | 450 | 150 | 117 |

| 10 | 250 | 24.50 | 622 | 24.50 | 622 | 32.00 | 815 | 16 | 400 | 280 | 245 | 24.50 | 622 | 25.12 | 638 | 35.50 | 900 | 20 | 500 | 360 | 310 |

| 12 | 300 | 27.50 | 698 | 27.50 | 698 | 35.88 | 910 | 18 | 450 | 380 | 345 | 28.00 | 711 | 28.62 | 727 | 38.62 | 980 | 24 | 600 | 550 | 492 |

| 14 | 350 | 31.00 | 787 | 31.00 | 787 | 48.38 | 1230 | 20 | 500 | 510 | 450 | - | - | - | - | - | - | - | - | - | - |

| 16 | 400 | 36.00 | 914 | 36.00 | 914 | 57.00 | 1450 | 24 | 600 | 740 | 665 | - | - | - | - | - | - | - | - | - | - |

| in | mm | in | mm | in | mm | in | mm | in | mm | RF | BW | in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW |

| Dimensional datas | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | DN | L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

||||||||||

| ANSI Class 600# | ANSI Class 900# | ||||||||||||||||||||

| 2 | 50 | 11.50 | 292 | 11.62 | 295 | 17.50 | 445 | 10 | 240 | 35 | 27 | 14.50 | 368 | 14.62 | 371 | 22.00 | 560 | 11 | 280 | 57 | 41 |

| 2½ | 65 | 13.00 | 330 | 13.12 | 333 | 19.75 | 502 | 11 | 280 | 50 | 34 | 16.50 | 419 | 16.62 | 422 | 23.25 | 590 | 13 | 320 | 82 | 53 |

| 3 | 80 | 14.00 | 356 | 14.12 | 359 | 21.00 | 533 | 13 | 320 | 60 | 42 | 15.00 | 381 | 15.12 | 384 | 25.25 | 640 | 16 | 400 | 91 | 58 |

| 4 | 100 | 17.00 | 432 | 17.12 | 435 | 24.50 | 622 | 16 | 400 | 110 | 84 | 18.00 | 457 | 18.12 | 460 | 31.88 | 810 | 18 | 450 | 168 | 117 |

| 6 | 150 | 22.00 | 559 | 22.12 | 562 | 29.50 | 750 | 18 | 450 | 230 | 192 | 24.00 | 610 | 24.12 | 613 | 41.38 | 1050 | 20 | 500 | 365 | 238 |

| 8 | 200 | 26.00 | 660 | 26.12 | 663 | 36.50 | 927 | 20 | 500 | 410 | 350 | 29.00 | 737 | 29.12 | 740 | 53.50 | 1360 | 24 | 600 | 1250 | 1060 |

| 10 | 250 | 31.00 | 787 | 31.12 | 790 | 44.88 | 1140 | 24 | 600 | 770 | 680 | 33.00 | 838 | 33.12 | 841 | 61.88 | 1570 | 24 | 600 | 1250 | 1060 |

| 12 | 300 | 33.00 | 838 | 33.12 | 841 | 53.12 | 1350 | 24 | 600 | 1140 | 1030 | - | - | - | - | - | - | - | - | - | - |

| in | mm | in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW | in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW |

| Dimensional datas | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | DN | L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

L/L1 (RF/BW) |

L2 (RTJ) |

H (open) |

D0 | WT (kg) |

||||||||||

| ANSI Class 1500# | ANSI Class 2500# | ||||||||||||||||||||

| 2 | 50 | 14.50 | 368 | 14.62 | 371 | 22.00 | 560 | 13 | 320 | 68 | 57 | 17.75 | 451 | 17.88 | 454 | 25.50 | 650 | 16 | 400 | 97 | 72 |

| 2½ | 65 | 16.50 | 419 | 16.62 | 422 | 23.25 | 590 | 16 | 400 | 97 | 81 | 20.00 | 508 | 20.50 | 414 | 28.12 | 715 | 18 | 450 | 138 | 95 |

| 3 | 80 | 18.50 | 470 | 18.62 | 473 | 29.50 | 750 | 18 | 450 | 116 | 95 | 22.75 | 578 | 23.00 | 584 | 32.50 | 825 | 20 | 500 | 167 | 108 |

| 4 | 100 | 21.50 | 546 | 21.62 | 549 | 36.00 | 915 | 20 | 500 | 215 | 184 | 26.50 | 673 | 26.88 | 683 | 47.00 | 1195 | 24 | 600 | 305 | 196 |

| 6 | 150 | 27.75 | 705 | 28.00 | 711 | 48.62 | 1235 | 24 | 600 | 445 | 347 | 36.00 | 914 | 36.50 | 927 | 70.50 | 1790 | 28 | 700 | 633 | 351 |

| 8 | 200 | 32.75 | 832 | 33.12 | 841 | 65.00 | 1650 | 28 | 700 | 795 | 635 | - | - | - | - | - | - | - | - | - | - |

| in | mm | in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW | in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW |