PRODUCT

Check valve

· Design

Cast steel check valves are designed and manufactured to provide maximum service life and dependability.

All check valves meet the design requirements of American Petroleum Institute standard API600 & 6D.BS EN 13709 and generally conform to American Society of Mechanical Engineers standard ASME B16.34.

Valves are available in a complete range of body/cover materials and trims.

· Ranges of materials

Standard body/cover materials include nine grades of carbon, low alloy and stainless steels,for special applications they can be supplied in other grades of alloy and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Available Modifications

Trim changes

End Connection Modifications

Packing and Gasket Change

Operator Mounting

Handwheel Extensions

Pressures Equalizing

Customer Specified Coatings

Weld End Bore Changes

Oxygen & Chlorine Clearing & Packaging

Applicable standards

STEEL CHECK VALVES, BS 1868/API 594/API 6D

STEEL VALVES, ASME B16.34

FACE TO FACE, ASME B16.10

END FLANGES, ASME B16.5

BUTTWELDING ENDS, ASME B16.25

INSPECTION AND TEST, API 598/API 6D

Design descriptions

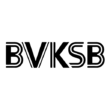

BC, BOLTED COVER

SWING TYPE, ANTI-ROTATION DISC

RENEWABLE SEAT RINGS

NON-PENETRATE DISC SHAFT

HORIZONTAL OR VERTICAL SERVICE

FLANGED OR BUTTWELDING ENDS

| Eyebolt | BC | End Connections | |||

|---|---|---|---|---|---|

| For 150Lb-8", 300Lb-8", 60OLb-6",900Lb/1500Lb/250OLb-4" & over. | Bolted cover.welded cover and pressure seal bonnet in services requiring frequent cycling or with high pressure/temperature variations. | A choice of flanged, RTJ flanged or buttwelding end for piping flexibility. | |||

| Body-to-Cover Joint | Outside Lever And Weight | Seat Rings | |||

| A male and female joint or tongue and groove joint is used 150Lb to 600Lb valves. Ring joint is used in the body to cover connection in 900Lb & higher rated valves. |

All external hinge pin swing check valves 12" and smaller are available with an optional outside lever and weight, internal hinge available with all swing check valves. | Separate heavy duty, full ported rings for easy maintenance. Screwed or welded connection into body. | |||

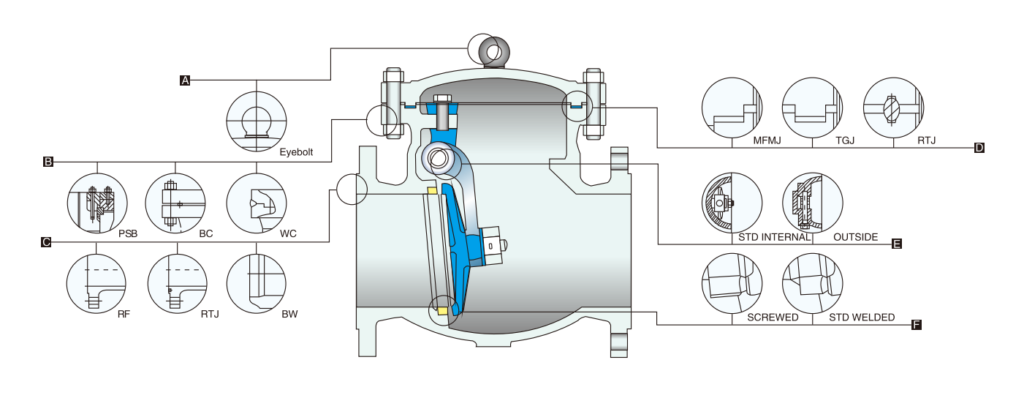

| Materials of parts | ||||

|---|---|---|---|---|

| No | Part Name | ASTM Material | ||

| Carbon steel | 1¼Cr-½Mo | Carbon Steel | ||

| 1 | Body | A216-WCB | A217-WC6 | A352-LCB |

| 2 | Cover | A216-WCB | A217-WC6 | A352-LCB |

| 3 | Disc 1) | A105+CR13 | A182-F11+HF | A350-LF2+CR13 |

| 4 | Hinge | A216-WCB | A217-WC6 | A352-LCB |

| 5 | Fork Part | A216-WCB | A217-WC6 | A352-LCB |

| 6 | Seat Ring | A105+CR13 | A182-F11+HF | A350-LF2+CR13 |

| 7 | Hinge Pin | A276-420 | A276-304 | A276-420 |

| 8 | Disc Washer | Carbon Steel | A276-304 | Carbon Steel |

| 9 | Disc Nut | Carbon Steel | A194-7 | Carbon Steel |

| 10 | Disc Nut Pin | Carbon Steel | A276-420 | Carbon Steel |

| 11 | Gasket | Spiral Wound(Graphite+304) | ||

| 12 | Stud | A193-B7 | A193-B16 | A320-L7 |

| 13 | Stud Nut | A194-2H | A194-7 | A194-4 |

| 14 | Eyebolt 2) | Carbon Steel | ||

| Note:1) Cast steel disc for NPS 4" and above. 2) NPS 6" & larger. 3) Disc and seat ring may either be solid facing material or a base material equal to or better than the body/bonnet material with facing as shown. |

||||

| Dimensional datas of ANSI Class 150# | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS DN | 2 | 2½ | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 36 | in |

| 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 900 | mm | |

| L/L1 (RF/BW) |

8.00 | 8.50 | 9.50 | 11.50 | 14.00 | 19.50 | 24.50 | 27.50 | 31.00 | 34.00 | 38.50 | 38.50 | 51.00 | 51.00 | 57.00 | 60.00 | 77.00 | in |

| 203 | 216 | 241 | 292 | 356 | 495 | 622 | 698 | 787 | 864 | 978 | 978 | 1295 | 1295 | 1448 | 1524 | 1956 | mm | |

| L2 (RTJ) |

8.50 | 9.00 | 10.00 | 12.00 | 14.50 | 20.00 | 25.00 | 28.00 | 31.50 | 34.50 | 39.00 | 39.00 | 51.50 | - | - | - | - | in |

| 216 | 229 | 254 | 305 | 368 | 508 | 635 | 711 | 800 | 876 | 991 | 991 | 1308 | - | - | - | - | mm | |

| H | 6.00 | 6.50 | 6.88 | 8.00 | 11.50 | 13.88 | 15.38 | 17.00 | 18.75 | 20.62 | 22.88 | 24.62 | 34.75 | 37.00 | 37.00 | 38.62 | 48.00 | in |

| 152 | 165 | 175 | 204 | 293 | 353 | 390 | 432 | 475 | 525 | 582 | 627 | 883 | 940 | 940 | 980 | 1220 | mm | |

| wt(kg) | 14 | 20 | 25 | 40 | 71 | 118 | 177 | 263 | 353 | 542 | 632 | 855 | 970 | 1600 | 1600 | 1990 | 2760 | RF/RTJ |

| 10 | 12 | 17 | 29 | 57 | 96 | 143 | 227 | 295 | 468 | 552 | 755 | 831 | 1420 | 1420 | 1760 | 2230 | BW | |

| Dimensional datas of ANSI Class 300# | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS DN | 2 | 2½ | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 36 | in |

| 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 900 | mm | |

| L/L1 (RF/BW) |

10.50 | 11.50 | 12.50 | 14.00 | 17.50 | 21.00 | 24.50 | 28.00 | 33.00 | 34.00 | 38.50 | 40.00 | 53.00 | 53.00 | 59.00 | 62.75 | 82.00 | in |

| 267 | 292 | 318 | 356 | 444 | 533 | 622 | 711 | 838 | 864 | 978 | 1016 | 1346 | 1346 | 1499 | 1594 | 2083 | mm | |

| L2 (RTJ) |

11.12 | 12.12 | 13.12 | 14.62 | 18.12 | 21.62 | 25.12 | 28.62 | 33.62 | 34.62 | 39.12 | 40.75 | 53.88 | 54.00 | 60.00 | 63.75 | - | in |

| 293 | 308 | 333 | 371 | 460 | 549 | 638 | 727 | 854 | 879 | 994 | 1035 | 1368 | 1372 | 1524 | 1619 | - | mm | |

| H | 6.00 | 6.50 | 6.88 | 8.00 | 11.50 | 13.88 | 15.38 | 17.00 | 18.75 | 20.62 | 22.88 | 24.62 | 34.75 | 35.88 | 37.00 | 38.62 | 48.00 | in |

| 152 | 165 | 175 | 204 | 293 | 353 | 390 | 432 | 475 | 525 | 582 | 627 | 883 | 910 | 940 | 980 | 1220 | mm | |

| wt(kg) | 16 | 23 | 29 | 46 | 82 | 136 | 204 | 302 | 405 | 625 | 730 | 985 | 1115 | 1465 | 1840 | 2290 | 3180 | RF/RTJ |

| 11 | 13 | 18 | 31 | 61 | 103 | 155 | 245 | 315 | 503 | 593 | 812 | 895 | 1205 | 1525 | 1895 | 2395 | BW | |

| Dimensional datas of ANSI Class 600# | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS DN | 2 | 2½ | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | in |

| 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | mm | |

| L/L1 (RF/BW) |

11.50 | 13.00 | 14.00 | 17.00 | 22.00 | 26.00 | 31.00 | 33.00 | 35.00 | 39.00 | 43.00 | 47.00 | 55.00 | in |

| 292 | 330 | 356 | 432 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 | mm | |

| L2 (RTJ) |

11.62 | 13.12 | 14.12 | 17.12 | 22.12 | 26.12 | 31.12 | 33.12 | 35.12 | 39.12 | 43.12 | 47.25 | 55.38 | in |

| 295 | 333 | 359 | 435 | 562 | 664 | 791 | 841 | 892 | 994 | 1095 | 1200 | 1407 | mm | |

| H | 7.50 | 8.00 | 8.75 | 10.00 | 14.50 | 17.50 | 19.25 | 21.38 | 23.38 | 25.75 | 28.75 | 31.00 | 43.50 | in |

| 190 | 205 | 222 | 255 | 368 | 445 | 490 | 540 | 595 | 655 | 730 | 785 | 1105 | mm | |

| wt(kg) | 24 | 35 | 44 | 70 | 125 | 207 | 310 | 460 | 615 | 945 | 1105 | 1495 | 1695 | RF/RTJ |

| 16 | 19 | 26 | 44 | 87 | 147 | 220 | 350 | 452 | 720 | 845 | 1160 | 1280 | BW | |

| Dimensional datas of ANSI Class 900# | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS DN | 2 | 2½ | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | in |

| 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | mm | |

| L/L1 (RF/BW) |

14.50 | 16.50 | 15.00 | 18.00 | 24.00 | 29.00 | 33.00 | 38.00 | 40.50 | 44.50 | 48.00 | 52.00 | - | in |

| 368 | 419 | 381 | 457 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | - | mm | |

| L2 (RTJ) |

14.62 | 16.62 | 15.12 | 18.12 | 24.12 | 29.12 | 33.12 | 38.12 | 40.88 | 44.88 | 48.50 | 52.50 | - | in |

| 371 | 422 | 384 | 460 | 613 | 740 | 841 | 968 | 1038 | 1140 | 1232 | 1334 | - | mm | |

| H | 9.50 | 10.00 | 11.00 | 12.50 | 18.12 | 22.00 | 24.00 | 26.50 | 29.38 | 32.00 | 33.50 | 38.75 | - | in |

| 240 | 256 | 278 | 320 | 460 | 560 | 610 | 675 | 745 | 815 | 850 | 985 | - | mm | |

| wt(kg) | 37 | 54 | 68 | 109 | 195 | 321 | 481 | 711 | 956 | 1468 | 1870 | 2316 | - | RF/RTJ |

| 21 | 25 | 34 | 58 | 115 | 194 | 290 | 461 | 597 | 950 | 1210 | 1533 | - | BW | |

| Dimensional datas of ANSI Class 1500# | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NPS | DN | L/L1 (RF/BW) |

L2 (RTJ) |

H | WT (kg) |

||||

| 2 | 50 | 14.50 | 368 | 14.62 | 371 | 9.50 | 240 | 40 | 29 |

| 2½ | 65 | 16.50 | 419 | 16.62 | 422 | 10.00 | 256 | 63 | 47 |

| 3 | 80 | 18.50 | 470 | 18.62 | 473 | 13.00 | 330 | 70 | 49 |

| 4 | 100 | 21.50 | 546 | 21.62 | 549 | 14.75 | 375 | 115 | 84 |

| 6 | 150 | 27.75 | 705 | 28.00 | 711 | 18.88 | 480 | 250 | 152 |

| 8 | 200 | 32.75 | 832 | 33.12 | 841 | 23.50 | 595 | 470 | 310 |

| 10 | 250 | 39.00 | 991 | 39.38 | 1000 | 26.00 | 660 | 740 | 470 |

| 12 | 300 | 44.50 | 1130 | 45.12 | 1146 | 29.12 | 740 | 1100 | 710 |

| 14 | 350 | 49.50 | 1257 | 50.25 | 1276 | 30.88 | 785 | 1410 | 910 |

| 16 | 400 | 54.50 | 1384 | 55.38 | 1407 | 32.88 | 835 | 1600 | 1100 |

| in | mm | in | mm | in | mm | in | mm | RF/RTJ | BW |

| Dimensional datas of ANSI Class 2500# | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NPS | DN | L/L1 (RF/BW) |

L2 (RTJ) |

H | WT (kg) |

||||

| 2 | 50 | 17.75 | 451 | 17.88 | 454 | 10.75 | 275 | 50 | 35 |

| 2½ | 65 | 20.00 | 508 | 20.25 | 514 | 13.25 | 335 | 76 | 55 |

| 3 | 80 | 22.75 | 578 | 23.00 | 584 | 13.75 | 350 | 85 | 68 |

| 4 | 100 | 26.50 | 673 | 26.88 | 683 | 15.12 | 385 | 165 | 115 |

| 6 | 150 | 36.00 | 914 | 36.50 | 927 | 19.50 | 495 | 460 | 225 |

| 8 | 200 | 40.25 | 1022 | 40.88 | 1038 | 24.62 | 625 | 900 | 580 |

| 10 | 250 | 50.00 | 1270 | 50.88 | 1292 | 28.00 | 712 | 1300 | 860 |

| 12 | 300 | 56.00 | 1422 | 56.88 | 1445 | 35.62 | 905 | 1800 | 1150 |

| 14 | 350 | - | - | - | - | - | - | - | - |

| 16 | 400 | - | - | - | - | - | - | - | - |

| in | mm | in | mm | in | mm | in | mm | mm | mm |